Well, I'm now looking for adapting AN3 hoses and accessories to the ST1300 metric standard. Banjo fittings are no issue as the banjo standard fits correctly, but AN has the thing that it's 37º instead of the 45º the ST1300 has on the mating surface, creating big problems when bearing the 200 bar the thing could reach when working in harsh conditions. I really don't understand why not rounding up those sizes so you don't end missmatching damn stuff for free. For motorcycles's sake...

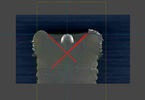

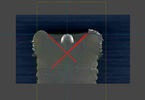

Well, I wanted to check the angle of those fittings in our ST1300, so I took a silicone plug I put in the PCV when cleaning it, cut it in half and put that thing in my scanner at maximum resolution. Then with GIMP I just checked the angle, being it of 90º, meaning a 45º from the longitudinal axis. AN3 has those stupid 37 drunk weirdo degrees, so I need adapters.

The scanned piece of hot glue showing clearly the angle, or good enough so you can be sure if it's 37 or 45º:

Fortunately AliExpress has those adapters for getting even a ravioli well fitted with the AN3 standard for 3€ in stainless steel, so the future seems not that bad. I just need 3 by the moment. Maybe tomorrow or so I'm doing a fancy shop list for the parts for creating the hoses. And maybe with just 50€ I'll be getting new and with good standards those 3 or 4 hoses I have more cracked than Windows.

One example of the many adapters in AliExpress: https://es.aliexpress.com/item/1005005369189214.html

I've seen in some of these AE products that the working pressure is 270 bar and the bursting pressure 400 bar. I don't trust them at all, ever. But, hey, I know my emergency brakings for my dear life could reach around 60 or 80 bar. It's good enough. I have plenty of margin for failures. And be sure I'll be happily jumping over that rear brake pedal when testing it, just to be sure it cannot burst or dissasemble when braking. I have big respect for brakes, suspension, tyres, bearings, steering, wheel balance, among few other basic passive security things.

I like where this brake issue, which worried me a bit, is going. Learning to create brake or hydraulic hoses and knowing where to get the parts is amazing.

------

I'm editing this post to add that I've just found this in AliExpress this part to adapt EXACTLY what we have in our motorcycles. I'm impressed:

Well, I wanted to check the angle of those fittings in our ST1300, so I took a silicone plug I put in the PCV when cleaning it, cut it in half and put that thing in my scanner at maximum resolution. Then with GIMP I just checked the angle, being it of 90º, meaning a 45º from the longitudinal axis. AN3 has those stupid 37 drunk weirdo degrees, so I need adapters.

The scanned piece of hot glue showing clearly the angle, or good enough so you can be sure if it's 37 or 45º:

Fortunately AliExpress has those adapters for getting even a ravioli well fitted with the AN3 standard for 3€ in stainless steel, so the future seems not that bad. I just need 3 by the moment. Maybe tomorrow or so I'm doing a fancy shop list for the parts for creating the hoses. And maybe with just 50€ I'll be getting new and with good standards those 3 or 4 hoses I have more cracked than Windows.

One example of the many adapters in AliExpress: https://es.aliexpress.com/item/1005005369189214.html

I've seen in some of these AE products that the working pressure is 270 bar and the bursting pressure 400 bar. I don't trust them at all, ever. But, hey, I know my emergency brakings for my dear life could reach around 60 or 80 bar. It's good enough. I have plenty of margin for failures. And be sure I'll be happily jumping over that rear brake pedal when testing it, just to be sure it cannot burst or dissasemble when braking. I have big respect for brakes, suspension, tyres, bearings, steering, wheel balance, among few other basic passive security things.

I like where this brake issue, which worried me a bit, is going. Learning to create brake or hydraulic hoses and knowing where to get the parts is amazing.

------

I'm editing this post to add that I've just found this in AliExpress this part to adapt EXACTLY what we have in our motorcycles. I'm impressed:

Last edited: