I re-installed the front wheel a few days ago and checked the clearance as part of the procedure. Doing so brought this to mind again and reminded me that there is no adjustment available as the right-hand fork can't be moved laterally on the axle like the left-hand side can, so it started me wondering again.

I forgot to answer this particular point - but the answer is an interesting one. (I think so anyway).

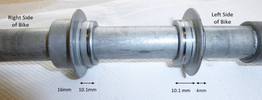

The axle is drawn across to the right as the axle bolt is tightend, and because of the shoulder on the left hand end of the axle, tightening pulls everything together and clamps them tight all against the right hand fork leg.

The Caliper Bracket is clamped firmly on the right hand fork leg. It is fixed and cannot move.

The Axle is also clamped firmly against the right hand fork leg

The bearings are also clamped against the right hand fork leg. For the front wheel, it is the right hand bearing that is driven in first, so it is that one that rests firmly on the hub of the wheel.

That being the case the wheel is firmly clamped in position relative to the right hand fork leg and the right hand cliper bracket.

In theory, do everything correctly and that 0.7mm space is there automatically.

But it does rely on those wheel collars being put on the correct side and the correct way round.

It also relies to a smaller extent on the right bearing being driven in first. (I think it is not a coincidence that the bearing to go in first is the one that is on the side of the tightening axle nut).

And it relies on the person assembling doing things in the correct order.

That last point is possibly the stumbling block for some people.

Not many people have a hex (allen key) driver that will fit in the hex socket at the end of the axles. Yet that axle needs to be prevented from turning.

Not many people realise that tightenting the axle bolt isn't just holding the axle in place - it is providing a clamping force for the entire axle assembly.

A lot of people use the trick of using the fork leg pinch bolts to clamp the axle so that the bolt can be tightened.

So it is not beyong the bounds of possibility for someone to remember this trick and apply it to the right hand axle pinch bolts, rather than to the left. It saves going round the other side, after all. Which allows the axle bolt to be torqued up, but which then prevents the axle from being pulled across to the right. So the wheel is able to slide on its axle - or the axle is now too long, So the clearance will disappear on at least one side.

But worse than that, when the other pinch bolts are tightened and the clearance obtained, the forks will be splayed, and the weight that was held by the axle bolt is now taken up by the pinch bolts. And that axle bolt will work loose. Especially if you do the bit about bouncing the forks.

We've had at least one example on these forums where a bike has suddenly lost its axle bolt, and I reckon that this was the reason for it.

So its not just the securing - it is doing things in the right order that is critical.

The same applies at the back for a different reason. That required the stopper bolt to be secured before the axle. Otherwise it could lock in an angular / alignment difference between the bracket and the bolt, which will knock the caliper out of alignment.