@jfheath I have read your brake bleeding guide once through now. Still digesting. Another well-known forum member mentioned a hard-to-get-to bleed valve (somewhere up under the fairings, I believe) but it was during a frenetic phone conversation and a lot was covered so I don't remember the particulars. What I do remember is he said the "normal" method of accessing this valve was to take 1/2 the motorcycle apart but that he had an alternate access method that was "simple". I was wondering if this rings any kind of bell and if you could enlighten me (my fall back is to ask him but since you have this nice brake bleed discussion going, I thought I'd take a shot here). I thought about PMing you on this but figured the discussion might be useful to others. Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Article [13] ST1300 - Brake Maintenance - Getting all the air out of the brake system

- Thread starter jfheath

- Start date

-

- Tags

- 1300 brakes

woodybelle

Site Supporter

I believe that Igofar has a way to get to the proportioning valve bleed nipple being the right middle cowl without removing the cowl entirely. Maybe he will chime in with the details.

I believe that Igofar has a way to get to the proportioning valve bleed nipple being the right middle cowl without removing the cowl entirely.

Correct ... to quote Larry from another post

As far as how to bleed the system without removing bodywork, I should have said the only one you'll have to remove is the right side cover (small, by battery) to gain access to the fluid.

The PCV can be reached simply by removing the rider's seat, and lifting the fuel tank up, once the tank is lifted your looking directly down on the bleed nipple alongside the frame spar.

The tubing goes in through the cylinder head area from the side, and your wrench/spanner reaches down from the open top etc.

Found in >> this thread <<

jfheath

John Heath

Thanks @staggart. I just take the fairing off, I usually have other stuff to do and clean up. @calderclay has quoted Larry's method above. I'm not a expert on that, but I would recommend a ring spanner on the bleed valve before putting the tube on. It avoids dropping the spanner. Also important to put a spring clip on the tube. Brake pressure will blow the tube off the valve, and you'll have to remove the fairing to clean up the fluid.

Some people might think that this is why I remove the fairing these days. I couldn't possibly comment. I am just suggesting what could happen.

Some people might think that this is why I remove the fairing these days. I couldn't possibly comment. I am just suggesting what could happen.

@woodybelle, @caldercay, @jfheath All 3 of you hit it on the head and referenced the mystery forum member as well  Thanks. @jfheath You mention using a vacuum pump for bleeding. Do you have a recommended one. Also, @Igofar says he does not use one (and that it can cause issues if misused (I think damaging seals, as I recall) , if I am not misquoting him).

Thanks. @jfheath You mention using a vacuum pump for bleeding. Do you have a recommended one. Also, @Igofar says he does not use one (and that it can cause issues if misused (I think damaging seals, as I recall) , if I am not misquoting him).

I just used this bleeder from Motion Pro & I completely replaced pistons, seals, pads front & rear on a 2007 ST1300 along with a new SMC unit last week , bled brakes 5 times and brakes are absolutely solid and front brake & rear pedal are firm....no problem using it, just go slow & methodically through sequence, air will bleed out...

- Joined

- Feb 11, 2006

- Messages

- 8,021

- Location

- Jacksonville

- Bike

- GL1800 R1200RT NC700

- 2025 Miles

- 005958

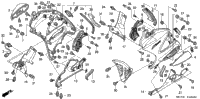

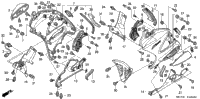

You can raise the upper gas tank to access the proportioning control valve and particularly do so if your service to do includes an air filter or perhaps a throttle body synch or valve check but if we are just servicing the brake fluid no need to raise the upper gas tank and risk tearing the upper tank to lower tank joint hose when you can access the PCV by removing a few bolts/screws and a plastic rivet and pulling the back edge of the right middle cowl out about 2" This 2" is plenty to reach in and get a wrench on the bleeder and the bleed hose snakes in through the opening in the fairing. The screws that need to remove are in this diagram are #21 & #19 to release the back of the black lower cowl. Leave the front #21 in place. You can remove that other 21 up front if you like and let the right lower cowl droop down but it's not necessary. Then pop off the tip over bar cover #4 after removing #20. Now remove the two #34s and secure the metal collars they pass through. Remove rivet #28 and lastly screw #22. Pull the back edge of the cowl free - it is fixed at the back edge with a male protrusion on the inside of the cowl that pops out of a female rubber grommet in the frame and with two male tabs that slip into slots on the body - colored cowl just below where rivet #28 went. With the cowl pulled loose and out a little I had a small block of wood, maybe 2 x 2", anything about this size will do, that I wedged between the frame and the cowl. This leaves enough room to reach in to access the PVC and bleed it. In the parts diagram the left cowl and parts are easier to see and understand - the right side is a mirror image. Find the fasteners in the left side diagram and then locate the ones on the right side, as the PVC is on the right side.

www.cyclepartsnation.com

www.cyclepartsnation.com

2005 Honda ST1300A ST1300 Lower Cowl

Shop online for OEM Lower Cowl parts that fit your 2005 Honda ST1300A ST1300, search all our OEM Parts or call at 269-385-1540

Last edited:

I just did my brake pads, SMC, and bled all the brake lines with @Igofar help. I used the one way valve bleeder (I did buy the vacuum bleeder as well) but Larry said I will not need it. I also did NOT remove the fairing to bleed the PCV as per Larry but I was struggling with the limited space to attach the bleed hose. I ended heating the bleed hose and to soften it and I was able to slide it on the nipple. Wasn’t easy but it worked! I was able to bleed all the brake lines solo with the Step 3 being the most tricky depressing the foot brakes AND SMC back and forth.

- Joined

- Feb 11, 2006

- Messages

- 8,021

- Location

- Jacksonville

- Bike

- GL1800 R1200RT NC700

- 2025 Miles

- 005958

A lot of us don't want to remove the right side middle cowl to bleed the brakes and as shown in this thread it is not necessary to bleed the PVC but in the scheme of things it isn't difficult at all and I think we should do it at least once to see how it all fits together. Sometimes I was riding my ST enough to be doing the brake service twice in a year and wanted to save a few minutes but when I did a full service with valves, coolant, and air filter I usually removed the fairing anyway.

jfheath

John Heath

I don't like using the vacuum pump. It can be messy, and it tends to suck air past the bleed valve threads - so you can never tell whether you are getting air out of the system or whether it is coming past the threads. I always finish off with the non return valve bleed tube, like the Motion Pro.

BUT - when there is air in the system, it gets trapped in odd places and I have found the vacuum pump to be extremely useful to have that sucking at the bleed valve, while I go round exercising brake pistons, master cylinders, the SMC flexing hoses and tapping joints. See that video of air bubbles trapped in coloured ink, hardly scientific, it gave me a better idea of where to chase bubbles from. As soon as the big bubbles stop coming out, and I just get a steady stream of smaller ones, then I switch to the non-return valve.

As for the vacuum damaging the pistons - I've not had that conversation with Larry, but if the fluid is 'flowing' in the correct direction as when the brakes are being operated, then I can't see an issue. There are non return valves in various places in the system, which would impede the movement of fluid in the wrong direction, and adding force might have unforseen consequences.

When I do my own fluid in the next couple of days, I'll be trying not to use the vacuum pump. There is no air in the system that I can feel - the brakes are nice and firm. But the fluid needs changing, so I'll be sluicing out the old stuff trapped behind the pistons, in the SMC etc etc. I can do that with conventional pumping and exercising pistons.

The PCV valve I have found to be an important place to get rid of air (its not quite the highest point). I've also expelled some pretty grungy fluid from someone's bike that was trapped between the SMC and that valve. I'm glad I didn't have to chase it round to the rear caliper.

BUT - when there is air in the system, it gets trapped in odd places and I have found the vacuum pump to be extremely useful to have that sucking at the bleed valve, while I go round exercising brake pistons, master cylinders, the SMC flexing hoses and tapping joints. See that video of air bubbles trapped in coloured ink, hardly scientific, it gave me a better idea of where to chase bubbles from. As soon as the big bubbles stop coming out, and I just get a steady stream of smaller ones, then I switch to the non-return valve.

As for the vacuum damaging the pistons - I've not had that conversation with Larry, but if the fluid is 'flowing' in the correct direction as when the brakes are being operated, then I can't see an issue. There are non return valves in various places in the system, which would impede the movement of fluid in the wrong direction, and adding force might have unforseen consequences.

When I do my own fluid in the next couple of days, I'll be trying not to use the vacuum pump. There is no air in the system that I can feel - the brakes are nice and firm. But the fluid needs changing, so I'll be sluicing out the old stuff trapped behind the pistons, in the SMC etc etc. I can do that with conventional pumping and exercising pistons.

The PCV valve I have found to be an important place to get rid of air (its not quite the highest point). I've also expelled some pretty grungy fluid from someone's bike that was trapped between the SMC and that valve. I'm glad I didn't have to chase it round to the rear caliper.

I may be misstating what he said on this. I talked with him in the last few hours and asked him about it. He did not confirm any damage being caused by vacuum pumps. I'm going all-in on the check-valve procedure with lots of tapping and patience. I'm still waiting on my SMC so I'm a few days out. You'll hear shouting from California when I startAs for the vacuum damaging the pistons - I've not had that conversation with Larry

Kevcules

Site Supporter

When I do my own fluid in the next couple of days, I'll be trying not to use the vacuum pump. There is no air in the system that I can feel - the brakes are nice and firm. But the fluid needs changing, so I'll be sluicing out the old stuff trapped behind the pistons, in the SMC etc etc. I can do that with conventional pumping and exercising pistons.

The PCV valve I have found to be an important place to get rid of air (its not quite the highest point). I've also expelled some pretty grungy fluid from someone's bike that was trapped between the SMC and that valve. I'm glad I didn't have to chase it round to the rear caliper.

JFHeath ....Would you consider doing a video of the entire bleeding process? This would sure help everyone to really see where the trouble spots are and the proper way to keep these awesome (NOT) brake systems working properly.

Last edited:

jfheath

John Heath

I could have a go. I have thought about it in the past, but poor light, tight space, the risk of transferring brake fkuid to camera body or lens, and the fact that my cameras have no monitor - so I cant see what I have filmed until the job is finished - have all put me off.

But I have 3 bullet cameras and 3 bleeders ( well, 2,5 since one of them doesn't stop reverse flow !} . So maybe with cameras capable of 4 hours continuous filming and a lot of editiing, it might be possible.

Looks like I'll be emptying my brake lines after all. Damn. I need more brake fluid.

But I am no 'expert' and I have never had any training in any aspect of maintaining motorcycles. So it can only ever be a record of what I do, not a definitive description of how it should be done.

I can only try. I'm just going outside and may be some time.

Ps - edited in after posting - @Kevcules - The ST1300 brakes ARE awesome - phenomenal stopping power with the ability to bring almost half a ton of motorcycle, riders and luggage to a rapid halt from high speeds without the rider losing control. The front lever alone, with just two fingers on the lever will do that, with just 6 of the 9 pistons applied. Add the foot pedal to apply the remaining 3 and the additional stopping power is instantly obvious.

They just need to be well maintained.

@staggart - re pumping the fluid - Larry has probably mentioned this, but I have never seen anyone post it, but it is mentioned by Honda. When pumping by hand it can be more effective to pump the lever rapidly a few times, hold the lever in on the last stroke and release the valve, closing the valve when the fluid stops flowing out. Only release the lever once the valve is closed again. Repeat.... Repeat......... What this seems to do is compress the air bubbles and pump up the flex in the brake hoses. The built up pressure forces the fluid and air down the line when the valve is opened. Keeping the lever held in prevents the pressure from escaping through the compensation port in the master cylinder.

When there is air in the system, opening the valve and pumping the lever has little effect, and the non return valve is not very effective either. The air just changes shape instead.

But I have 3 bullet cameras and 3 bleeders ( well, 2,5 since one of them doesn't stop reverse flow !} . So maybe with cameras capable of 4 hours continuous filming and a lot of editiing, it might be possible.

Looks like I'll be emptying my brake lines after all. Damn. I need more brake fluid.

But I am no 'expert' and I have never had any training in any aspect of maintaining motorcycles. So it can only ever be a record of what I do, not a definitive description of how it should be done.

I can only try. I'm just going outside and may be some time.

Ps - edited in after posting - @Kevcules - The ST1300 brakes ARE awesome - phenomenal stopping power with the ability to bring almost half a ton of motorcycle, riders and luggage to a rapid halt from high speeds without the rider losing control. The front lever alone, with just two fingers on the lever will do that, with just 6 of the 9 pistons applied. Add the foot pedal to apply the remaining 3 and the additional stopping power is instantly obvious.

They just need to be well maintained.

@staggart - re pumping the fluid - Larry has probably mentioned this, but I have never seen anyone post it, but it is mentioned by Honda. When pumping by hand it can be more effective to pump the lever rapidly a few times, hold the lever in on the last stroke and release the valve, closing the valve when the fluid stops flowing out. Only release the lever once the valve is closed again. Repeat.... Repeat......... What this seems to do is compress the air bubbles and pump up the flex in the brake hoses. The built up pressure forces the fluid and air down the line when the valve is opened. Keeping the lever held in prevents the pressure from escaping through the compensation port in the master cylinder.

When there is air in the system, opening the valve and pumping the lever has little effect, and the non return valve is not very effective either. The air just changes shape instead.

Last edited:

Somebody should video Larry bleeding the brakes and other servicing jobs on the ST. The BMW f-650 forum had a series of most of the service jobs that were available on a DVD or Youtube. I'd gladly buy a copy.

Kevcules

Site Supporter

Somebody should video Larry bleeding the brakes and other servicing jobs on the ST. The BMW f-650 forum had a series of most of the service jobs that were available on a DVD or Youtube. I'd gladly buy a copy.

No kidding? Great idea....I wish someone else would have asked about that before.

I think Larry is camera shy.

I think Larry is camera shy. That's why I suggested the job to JFHeath.....wait till you see the thorough job he does for this site! Looking forward to it.....

jfheath

John Heath

Kind words. Thank you. I'm onto it. By that, I mean I have cleared the rubbish from off my bench, swept the garage floor, got the bike on the ramp. Found a few camera angles that might work. Need to fashion a high tech broom handle or similar to hold the cameras in place. And I have finished the obligatory side track - which was to get the fairing off, fix a broken lead and repair a duff main connector, and identify some parts that I need to order before the UK and Europe (where the big Honda warehouses are) close the borders on 31 December.

@jfheath Hi John, I wonder if you can help me, you seem to be the guru on ST1300 brakes. I've read loads of stuff you (and Igofar) have published, tried to put it into practice & failed miserably.

Brief time line: 2007 ST13 52k on the clock - failed MOT (due to shamefully poor maintenance) including binding rear brake. Removed the caliper, cleaned & greased the pistons, re-assembled, new pads (EBC) font & rear, greased SMC roller bearing & bled the system per a Youtube video using a large syringe to create vacuum. Took a while, but I think (or thought until I read "Going on an air hunt") I did a reasonable job. Both hand & foot brake appeared to be firm. Failed 2nd MOT, rear still binding, if anything worse.

Found your article "Avoiding pitfalls..." - Cleaned & greased calipers properly, checked orientation of spring clips, cleaned & lubed sliding pins. Calipers now doing what they are supposed to do, i.e. sliding on the pins, pistons returnable with thumb pressure, dab of copper grease on the end of the pads & a smear on the back (No shims). Exercised the SMC, seems to move smoothly, cleared the drain hole (no obvious debris). Relieved the pressure in the SMC through the rear bleed valve after returning the pistons.

On the ramp still; the rear brake still locks hard with application of the foot brake. It appears to release after a several seconds, but still drags a little. It also appears that all 3 pistons react to the foot brake.

I am flummoxed, not sure what my next move is. My instinct is the SMC is the problem, although I have no real evidence to back that up. Any pearls of wisdom that may point me in the right direction?

I've got an ST1100 too, which has sat in the garage for the last 3 years with a substantially similar problem waiting for flash of inspiration.

Brief time line: 2007 ST13 52k on the clock - failed MOT (due to shamefully poor maintenance) including binding rear brake. Removed the caliper, cleaned & greased the pistons, re-assembled, new pads (EBC) font & rear, greased SMC roller bearing & bled the system per a Youtube video using a large syringe to create vacuum. Took a while, but I think (or thought until I read "Going on an air hunt") I did a reasonable job. Both hand & foot brake appeared to be firm. Failed 2nd MOT, rear still binding, if anything worse.

Found your article "Avoiding pitfalls..." - Cleaned & greased calipers properly, checked orientation of spring clips, cleaned & lubed sliding pins. Calipers now doing what they are supposed to do, i.e. sliding on the pins, pistons returnable with thumb pressure, dab of copper grease on the end of the pads & a smear on the back (No shims). Exercised the SMC, seems to move smoothly, cleared the drain hole (no obvious debris). Relieved the pressure in the SMC through the rear bleed valve after returning the pistons.

On the ramp still; the rear brake still locks hard with application of the foot brake. It appears to release after a several seconds, but still drags a little. It also appears that all 3 pistons react to the foot brake.

I am flummoxed, not sure what my next move is. My instinct is the SMC is the problem, although I have no real evidence to back that up. Any pearls of wisdom that may point me in the right direction?

I've got an ST1100 too, which has sat in the garage for the last 3 years with a substantially similar problem waiting for flash of inspiration.

new pads (EBC) font & rear,

This doesn't address your overall issue, but it's preferable to NOT use EBC and only use factory pads for the ST.

jfheath

John Heath

On the face of it, you seem to have everything covered. Yet your rear brakes are still locking up, so something isn't right.

Greased the calipers? I put red rubber grease on the exposed part of the pistons. Some people don't bother, but in the UK with exposure to grit and salt from the roads, I prefer to clean off a greasy sludge than to have the grit attacking the surface of the pistons. My choice.

The slider pins need greasing but use silicone or rubber grease. Other greases will cause the rubber boots to swell. Did you note the bit about putting too much grease in the hole that the slider pins mate with ? It can create an air lock which pushes the caliper back across to make the brakes rub.

The pad spring. Check those tags on the narrow strip - the part of the spring furthest away from the pistons. Make sure that they are not bent or squashed flat. They are there to keep the inner pad from moving.

You have fitted EBC pads. EBC pads are the same thickness as the front pads - sort of pre-worn ! That means that when you put the pads in, there is plenty of room for them. It is possible to get the pads out of position at the deepest end of the caliper. Look through the wheel spokes from the right hand side to check. For the left hand side, you need to look behind the hose that runs over the stopper bolt. For that, you need to swing the left exhaust out of the way.

EBC don't come with heat shields, and the ST1300 needs them to be fitted - but that is not the cause of your problem.

EBC used to supply the same pads for front and rear. I don't know if they still do. The OEM rear pads have a notch in the tab end of the pad. The front pads do not.

Front Pad

Rear Pad

All calipers have a retainer clip like this:

This is the clip for the rear caliper. It has two parts that are punched from this side which form a ridge on the other side. That ridge is designed to mate with the notch in tab end of the rear pads.

If you have accidentally fitted front pads to the rear, or those retainer clips have been accidentally switched, the pads will find it difficult to move away fromt he disc when the pressure is released. The same thing will happen if it is the front left brake that is dragging - as that will cause the rear brake to be applied due to the action of the SMC when the bike is moving.

All of the above are quite easy to check.

But Lets get onto finding out why the rear caliper is not releasing the brakes.

The rear brake pedal will operate all three pistons of the rear caliper when the bike is stationary. The centre piston is operated directly from the line from the rear master cylinder backwards to the rear caliper.

The outer two pistons are also operated by the rear brake pedal - the rear master cyclinder has two lines attached to it. One of them goes to the front of the bike, applies the front brake's centre piston (first the left, and then the right if pressure is increased). It pumps fluid through the SMC which pushes its way past the primary seal of the piston. (All brake master cylinders allow fluid to flow from behind the seal, but prevent fluid from getting past from the front (where the pressure is). The line then goes up to the proportional control valve (front right of petrol tank), and down to the rear calipers.

Fluid needs to be able to escape from this line so if the SMC primary seal is in its correct position, it exposes a very tiny hole, which allows the fluid to escape. The Rear pedal master cyclinder also has a tiny escape hole (called a compensation port), which allows excess fluid to get back into the reservoir. If the reservoir is full, the excess has nowhere to go, and the pressure in the system cannot be released.

It can be difficult to return the two outer pistons in the rear caliper using just thumb pressure as it has a lot of plumbing to go through and three tiny compensation ports to go through.

The most common fault is that the SMC is not returning properly - often due to corrosion inside the bore, or a blocked compensation port.

Put the bike into neutral. Check that the rear wheel is free to spin. Lie down alongside the bike and turn the back wheel with your foot. Activate the SMC by pushing the front left caliper bracket towards the fork leg. It should only move 1 to 1.5mm, so don't expect it to move like a brake lever. Check that the rear wheel can no longer be turned when the SMC is activated.

Release the SMC and check that the rear wheel can turn again. If it is binding, then there is a pretty good chance that the problem is due to a faulty SMC.

In this case, it needs to be replaced. But do the checks and feed back. You are welcome to PM me if you prefer.

Whereabouts in the UK are you ?

Cleaned & greased calipers properly, checked orientation of spring clips, cleaned & lubed sliding pins.

Greased the calipers? I put red rubber grease on the exposed part of the pistons. Some people don't bother, but in the UK with exposure to grit and salt from the roads, I prefer to clean off a greasy sludge than to have the grit attacking the surface of the pistons. My choice.

The slider pins need greasing but use silicone or rubber grease. Other greases will cause the rubber boots to swell. Did you note the bit about putting too much grease in the hole that the slider pins mate with ? It can create an air lock which pushes the caliper back across to make the brakes rub.

The pad spring. Check those tags on the narrow strip - the part of the spring furthest away from the pistons. Make sure that they are not bent or squashed flat. They are there to keep the inner pad from moving.

You have fitted EBC pads. EBC pads are the same thickness as the front pads - sort of pre-worn ! That means that when you put the pads in, there is plenty of room for them. It is possible to get the pads out of position at the deepest end of the caliper. Look through the wheel spokes from the right hand side to check. For the left hand side, you need to look behind the hose that runs over the stopper bolt. For that, you need to swing the left exhaust out of the way.

EBC don't come with heat shields, and the ST1300 needs them to be fitted - but that is not the cause of your problem.

EBC used to supply the same pads for front and rear. I don't know if they still do. The OEM rear pads have a notch in the tab end of the pad. The front pads do not.

Front Pad

Rear Pad

All calipers have a retainer clip like this:

This is the clip for the rear caliper. It has two parts that are punched from this side which form a ridge on the other side. That ridge is designed to mate with the notch in tab end of the rear pads.

If you have accidentally fitted front pads to the rear, or those retainer clips have been accidentally switched, the pads will find it difficult to move away fromt he disc when the pressure is released. The same thing will happen if it is the front left brake that is dragging - as that will cause the rear brake to be applied due to the action of the SMC when the bike is moving.

Did you check the level of fluid in the rear reservoir after doing this ? Although I note that later you released fluid via the rear bleed valves.pistons returnable with thumb pressure

All of the above are quite easy to check.

But Lets get onto finding out why the rear caliper is not releasing the brakes.

The rear brake pedal will operate all three pistons of the rear caliper when the bike is stationary. The centre piston is operated directly from the line from the rear master cylinder backwards to the rear caliper.

The outer two pistons are also operated by the rear brake pedal - the rear master cyclinder has two lines attached to it. One of them goes to the front of the bike, applies the front brake's centre piston (first the left, and then the right if pressure is increased). It pumps fluid through the SMC which pushes its way past the primary seal of the piston. (All brake master cylinders allow fluid to flow from behind the seal, but prevent fluid from getting past from the front (where the pressure is). The line then goes up to the proportional control valve (front right of petrol tank), and down to the rear calipers.

Fluid needs to be able to escape from this line so if the SMC primary seal is in its correct position, it exposes a very tiny hole, which allows the fluid to escape. The Rear pedal master cyclinder also has a tiny escape hole (called a compensation port), which allows excess fluid to get back into the reservoir. If the reservoir is full, the excess has nowhere to go, and the pressure in the system cannot be released.

It can be difficult to return the two outer pistons in the rear caliper using just thumb pressure as it has a lot of plumbing to go through and three tiny compensation ports to go through.

The most common fault is that the SMC is not returning properly - often due to corrosion inside the bore, or a blocked compensation port.

Put the bike into neutral. Check that the rear wheel is free to spin. Lie down alongside the bike and turn the back wheel with your foot. Activate the SMC by pushing the front left caliper bracket towards the fork leg. It should only move 1 to 1.5mm, so don't expect it to move like a brake lever. Check that the rear wheel can no longer be turned when the SMC is activated.

Release the SMC and check that the rear wheel can turn again. If it is binding, then there is a pretty good chance that the problem is due to a faulty SMC.

In this case, it needs to be replaced. But do the checks and feed back. You are welcome to PM me if you prefer.

Whereabouts in the UK are you ?

Last edited:

Sadlsor

Site Supporter

@staggart should have received his SMC by now. I ordered mine and got it in about a week or less, from Ron Ayers.

(Where's your SMC replacement and brake-bleeding video, @staggart ? -- I kid.)

So, in Post 1, @jfheath has a helpful PDF which I've printed, then in Post 2 is a link to another bit of info with pictures -- but it's a broken link. Does that reference the same PDF file from Post 1?

I haven't heard the shouting from California, so maybe @staggart hasn't completed his SMC swap-out .

Tomorrow is the day for me and ST.

But I don't shout well, so I'll just post it around here somewhere when done (or when stuck)... and I'm not promising a video, either.

(Where's your SMC replacement and brake-bleeding video, @staggart ? -- I kid.)

So, in Post 1, @jfheath has a helpful PDF which I've printed, then in Post 2 is a link to another bit of info with pictures -- but it's a broken link. Does that reference the same PDF file from Post 1?

I haven't heard the shouting from California, so maybe @staggart hasn't completed his SMC swap-out .

Tomorrow is the day for me and ST.

But I don't shout well, so I'll just post it around here somewhere when done (or when stuck)... and I'm not promising a video, either.

Share: