CYYJ

Michael

Much has been written about the importance of properly lubricating the final drive with moly paste whenever the rear wheel is removed.

Not so much has been written about the importance of ensuring that the three O-rings in the final drive are checked to ensure that they are in good condition, this to enable the three O-rings to keep the moly paste inside where it belongs, and to prevent dirt from entering into the area where the moly paste is and causing excessive wear of the final drive.

I get about 8,000 km (5,000 miles) out of a rear tire on my ST 1100. Every second rear tire change - in other words, every 10,000 miles - I replace the three O-rings in the final drive area. They are inexpensive (less than $10 for the set of three), and I believe that replacing them before they wear out is cheap insurance against having to spend well over $1,000 to replace the final drive assembly.

Two of the O-rings are relatively easy to find: they are located on the rear wheel assembly and you can see them on the wheel assembly when you remove the rear wheel. The third O-ring is often overlooked, because it resides in the final drive itself, and the final drive remains attached to the motorcycle when you remove the rear wheel.

Below are parts diagrams that illustrate the three O-rings, and pictures showing where to find these three O-rings. The parts diagrams and part numbers given are for my 2001 ST 1100, but I believe that the part numbers are the same for all ST 1100s.

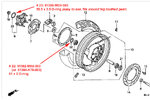

Parts Diagram for the two O-rings that are attached to the wheel:

A picture of the most obvious O-Ring (#23 in the diagram above):

The O-ring is covered in moly paste, sorry about that

A picture of the other O-Ring in the above parts diagram, which you will see once you remove the "spider" shown in the photo above:

For unknown reasons, there are two part numbers that can be used for the same part

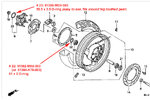

Parts Diagram for the O-ring on the final drive:

This is the O-ring that most people fail to inspect and/or replace. It is difficult to see unless you know where to look for it.

A photo of where to find the above-mentioned O-Ring:

The O-ring is missing in this photo, but you can see the groove it fits into at the tip of the red crayon

What happens if the third O-Ring (91356-MG9-004 in the picture above) is missing:

Back in the winter of 2008, an apprentice at my dealer in Zurich replaced the rear tire on my moto. He removed the three O-rings to replace them, but the youngster forgot to install the O-ring inside the final drive (photo directly above). The next time I went in for a rear tire change, 9,000 km (6,000 miles) later, the master mechanic did the work, and he was horrified to find that the final drive assembly (the spider, and the matching gear in the final drive) were almost destroyed. Some investigation determined that the apprentice had forgot to install the third O-ring at the previous tire change.

The damage you see in the picture below happened in just 6,000 miles of riding, much of which was in rainy weather. Water and dirt got into the final drive and caused excessive wear on the gears. The dealer was honourable and replaced all the components at their expense - but it was awfully expensive for them to do this.

Moral of the story: Carefully check the condition of these three O-rings every time you change the rear tire, and consider replacing the three O-rings on a regular schedule, before they fail and let dirt get into the final drive.

Not so much has been written about the importance of ensuring that the three O-rings in the final drive are checked to ensure that they are in good condition, this to enable the three O-rings to keep the moly paste inside where it belongs, and to prevent dirt from entering into the area where the moly paste is and causing excessive wear of the final drive.

I get about 8,000 km (5,000 miles) out of a rear tire on my ST 1100. Every second rear tire change - in other words, every 10,000 miles - I replace the three O-rings in the final drive area. They are inexpensive (less than $10 for the set of three), and I believe that replacing them before they wear out is cheap insurance against having to spend well over $1,000 to replace the final drive assembly.

Two of the O-rings are relatively easy to find: they are located on the rear wheel assembly and you can see them on the wheel assembly when you remove the rear wheel. The third O-ring is often overlooked, because it resides in the final drive itself, and the final drive remains attached to the motorcycle when you remove the rear wheel.

Below are parts diagrams that illustrate the three O-rings, and pictures showing where to find these three O-rings. The parts diagrams and part numbers given are for my 2001 ST 1100, but I believe that the part numbers are the same for all ST 1100s.

Parts Diagram for the two O-rings that are attached to the wheel:

A picture of the most obvious O-Ring (#23 in the diagram above):

The O-ring is covered in moly paste, sorry about that

A picture of the other O-Ring in the above parts diagram, which you will see once you remove the "spider" shown in the photo above:

For unknown reasons, there are two part numbers that can be used for the same part

Parts Diagram for the O-ring on the final drive:

This is the O-ring that most people fail to inspect and/or replace. It is difficult to see unless you know where to look for it.

A photo of where to find the above-mentioned O-Ring:

The O-ring is missing in this photo, but you can see the groove it fits into at the tip of the red crayon

What happens if the third O-Ring (91356-MG9-004 in the picture above) is missing:

Back in the winter of 2008, an apprentice at my dealer in Zurich replaced the rear tire on my moto. He removed the three O-rings to replace them, but the youngster forgot to install the O-ring inside the final drive (photo directly above). The next time I went in for a rear tire change, 9,000 km (6,000 miles) later, the master mechanic did the work, and he was horrified to find that the final drive assembly (the spider, and the matching gear in the final drive) were almost destroyed. Some investigation determined that the apprentice had forgot to install the third O-ring at the previous tire change.

The damage you see in the picture below happened in just 6,000 miles of riding, much of which was in rainy weather. Water and dirt got into the final drive and caused excessive wear on the gears. The dealer was honourable and replaced all the components at their expense - but it was awfully expensive for them to do this.

Moral of the story: Carefully check the condition of these three O-rings every time you change the rear tire, and consider replacing the three O-rings on a regular schedule, before they fail and let dirt get into the final drive.